Onboard Computing Shelf

Project Overview

This page summarizes one of the projects I am able to share from Hitachi. This design is for an onboard computer shelf structure for commuter locomotives.

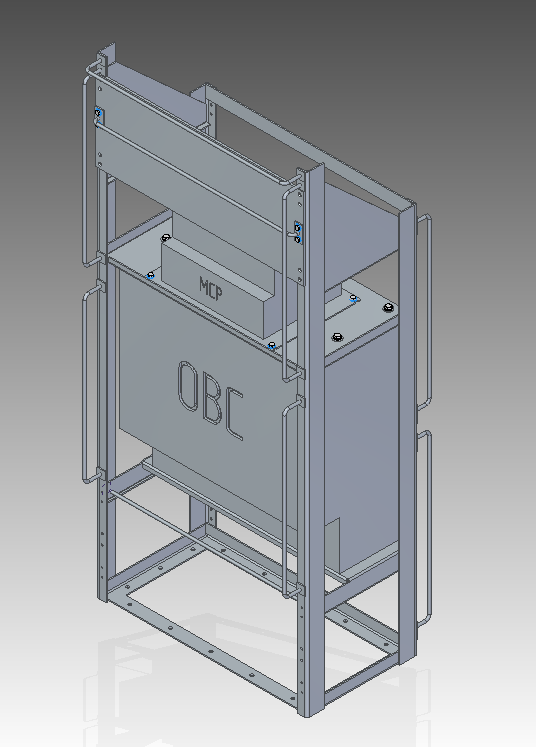

On-board Computer Shelf

This image displays a 3D rendering of the shelf in CAD. This includes the welded frame, the bolted components, and reference parts including the bodies labeled OBC, MCP, and the front plate at the top of the frame. These reference parts were added at the request of the customer to supplement the assembly drawings.

Project Goal

I was tasked with creating a structure that would support computing equipment aboard commuter trains for a notable northeast U.S. transit system. The project gave me full control of the design (pending requestor approval) and had the following constraints:

- Size: Due to space limitations on the train.

- Material: For strength, manufacturability, and vendor agreements.

- Handedness: Not all trains are equivalent, so some adjustability for cable management was required.

This design incorporated aspects of Design for Manufacturability (DFM) as well as Design for Assembly (DFA).

Main Challenges

The computing eqiupment supported by this structure are both cumbersome and heavy meaning the structure would need to support the equipment’s weight and inertia as the train moves throughout the trips. Also, since the structure is supporting computer equipment, the design may not prohibit the installer from managing the cables to the computing equipment effectively. Lastly, this structure needs to be simple to manufacture to minimize costs and assembly time.

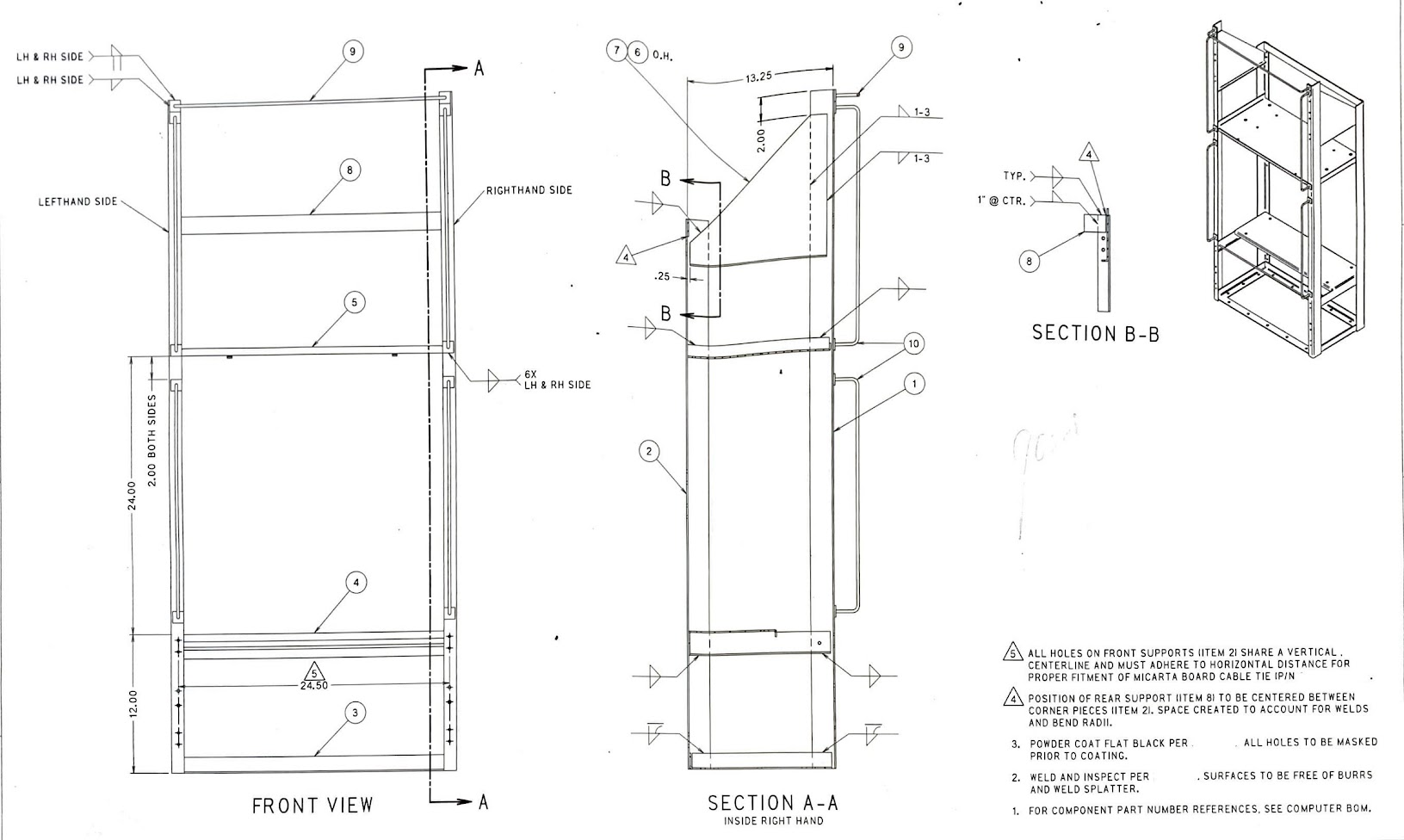

For these reasons, I landed on a design involving a welded and painted steel sheet metal frame with bolted joints for certain cable ties and computing equipment for easy assembly and removal.

Design

These attached images (click to enlarge) are abridged portions of the designs for this shelf structure. They showcase assembly information, reference parts, detail views, weld instrutions, and sectional views. The cable tie, as shown by the second delta note, can be removed and attached to the opposite side depending on the locomotive this structure will accomodate.

It should be noted that privileged information regarding part numbers, bill of materials (BOM), specification numbers, and subassembly information have been excluded at the request of the company.

Results

This design was successfully implemented by the transit authority within one month of completion.

Disclaimer

This design has been shared with the permission of Hitachi Rail STS. Private information regarding the design specifications, part numbers, and any vendor or customer information have been excluded from this post to protect the intellectual property of the company.